It was a great project to work on and we had a lot of fun doing it. Hopefully, some of our changes will be implemented to the Arena Racing roll cage!

Arena Racing VCU SoE

This website is dedicated to the progress of a senior design project at VCU's School of Engineering focused on the optimization of the current Arena Racing USA roll cage model. This design will be modeled and tested throughout the rest of the Fall of 2013 and Spring of 2014 semesters. The design attempts to improve the current roll cage for cost, safety, and ease of build.

Senior Design Expo 2014

The Senior Design Expo was a lot of fun. It was great to showcase our project amongst the other teams who took on this project. Here's a picture of our team with our poster:

The Modified Roll Cage

After many trial and errors, we have come up with our final modified roll cage! Here it is:

Our design has greatly simplified the roll cage, as well as maintained the same level of safety. In total, we took out 18 welds and 8 bends from the 106 welds and 26 bends total. That corresponds to a 17% decrease in welding time and a savings of 14 ft of material!

Here are side-by-side views of the major changes:

Per roll cage, we saved about $153! That could amount to a $153,000 annual savings for Arena Racing if they reach their goal of selling 1,000 annually. We are really proud of our work.

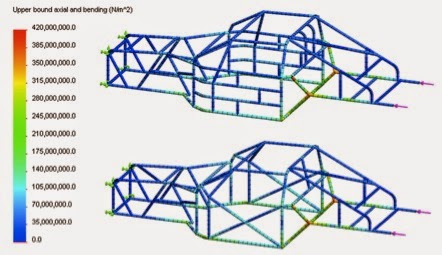

Also, the safety of the driver nor the integrity of the roll cage were compromised. Here are the stress analysis to compare:

This is a front loading collision at 25 mph with the modified model on the bottom.

Here is a back loading collision:

We worked really hard to achieve this over Spring Break. Here we are in the West Hall:

Early Spring 2014 semester

The team had hopes of attending an Arena Racing race for the purpose of confirming certain measurements of the roll cage, but that never happened. We did clean up our model quite a bit. Here is the finished original model:

It looks great! The next part was the most challenging because it took multiple stress tests and calculations to ensure the structure would not fail, and above all, that the driver would be safe.

We spent many meetings taking out bars, conducting stress analysis, putting bars back in, conducting more stress analysis, and so on.

We really need to make sure that not only are we maintaining the same level of safety, but that we are decreasing the cost of the car to actually make the changes worthwhile.

SolidWorks Model

Modeling the stock car on SolidWorks proved to be a tediously long process. Because there were so many curves on the stock car, it was difficult to obtain really accurate dimensions to model. There was a lot of estimating and guessing. We modeled the front, middle, back, then top. When it was time to do a stress analysis, there was an issue with meshing. So, simplifications had to be made to certain curves and corners of the stock car. All in all, our team's model turned out great.

Arena Racing Stock Car

An Arena Racing stock car was dropped off at VCU for the teams to take dimensions of it. With these dimensions, a model could be made on SolidWorks.

What is Arena Racing?

This project is based around the Arena Racing USA League, founded by Ricky Dennis in 2002. Arena Racing is a stock car racing company whose 2013 season runs from November to April. Currently, it only exists in Richmond, VA, at the Richmond Coliseum. Over the next ten years, Arena Racing plans to spread to multiple cities around the United States. Before expansion can begin, their current stock car needs to be improved. Conceptualizing, designing, testing, and possibly implementing these improvements is the objective of this project.

The current car is a half scale model of a full size stock car. All cars participating in Arena Racing are identical and sold only by Arena Racing. Additionally, there are certain restrictions and constraints on how race teams may alter or manipulate their car. The purpose is to keep all cars and equipment equal. This promotes the League’s primary focus of maintaining a skill-based racing competition.

Subscribe to:

Comments (Atom)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)